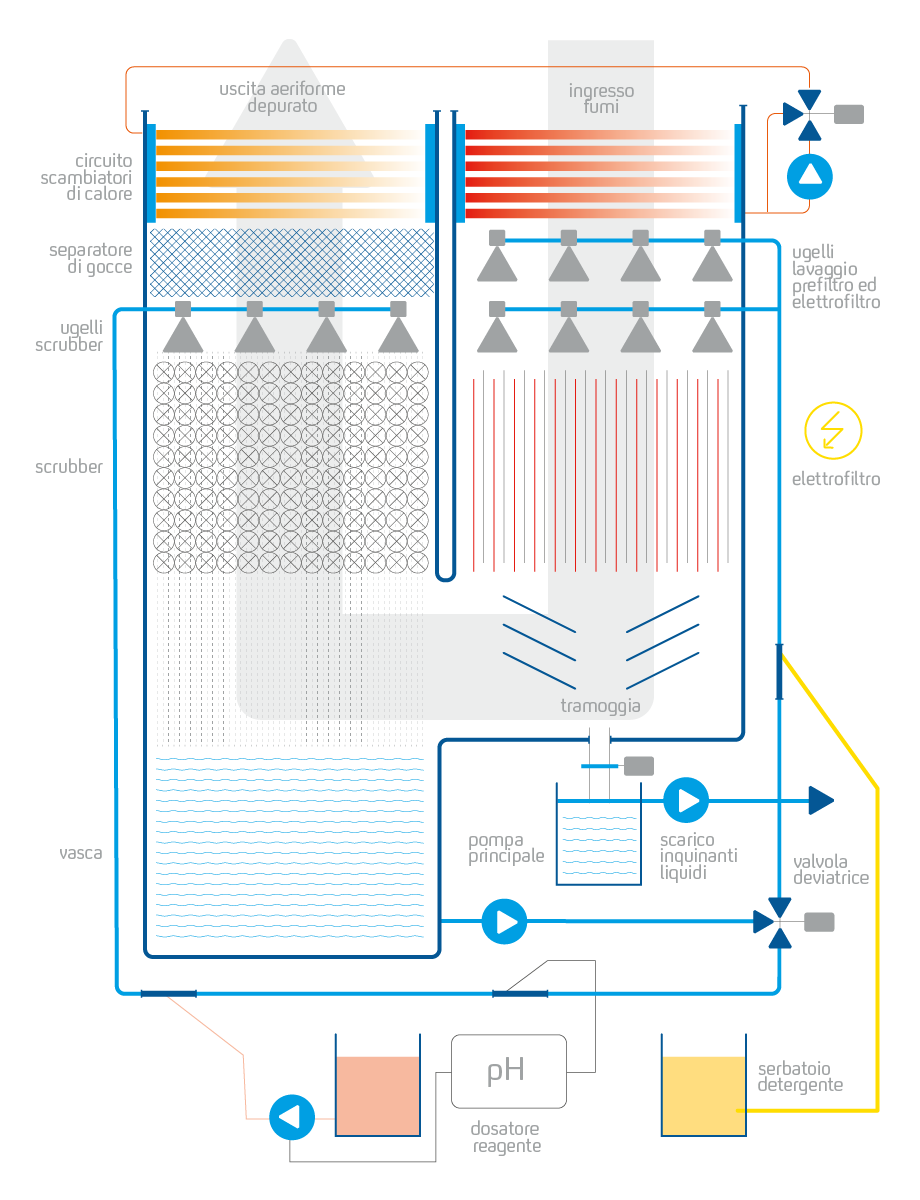

The K-IND® industrial purifier is a machine with great flexibility as it encloses an electrostatic precipitator and a wet scrubber, two complementary types of filter by range of action, in a single structure.

Many industrial productions are characterized by complex pollutant emissions, i.e. composed of a mixture of different substances from a chemical-physical point of view, impossible to treat effectively in a single solution.

In these cases Deparia proposes an exclusive, effective and widely tested system: the K-IND® industrial purifier, a special combined machine that contains several stages of emission abatement, based on different specific technologies for different fractions of pollutants.

A special electro-filter retains substances in the form of aerosols or particulates, while pollutants in gaseous and vapor form are absorbed chemically, with ozone induction.

Industrial purifier for the broad-spectrum abatement of emissions of different pollutants.

Self-cleaning.

Protects against fire risk .

Rubber processing, plastic processing and chemical industry

Food sector

Textile industry

INDUSTRY: industrial gasket molding (Bergamo).

EMISSIONS: VOS, particulates, oil mist, from molding presses and post-galvanization ovens.

SYSTEM: n° 3 K-IND® purifiers and one customized KAPPA purifier.

INDUSTRY: textile (Milan).

EMISSIONS: emissions from fiberglass net production.

SYSTEM: n° 4 K-IND®.

INDUSTRY: industrial gasket molding (Lecco).

EMISSIONS: VOS, particulates.

SYSTEM: combined K-IND® machine.