Abatement of volatile organic substances found in most industrial emissions

Zeolite-based rotor-concentrators are used for the abatement of volatile organic substances found in most industrial emissions, in case of low concentration of pollutants and high gas flow rate.

The volatile organic compounds contained in the airflow are concentrated by adsorption in the concentrator consisting of the zeolite rotor. The clean air flow is sent directly to the chimney. The pollutants concentrated in the rotor-concentrator are desorbed and finally treated by a small thermal oxidizer.

Ideal at high emission rates and relatively low solvent concentrations.

Low management and maintenance costs .

Reduced oxidizer plant dimensioning.

Chemical industry

Pharmaceutical industry

Food sector

Painting and coatings

Printing industry

For more information about the Rotor-Concentrators download the technical data sheet.

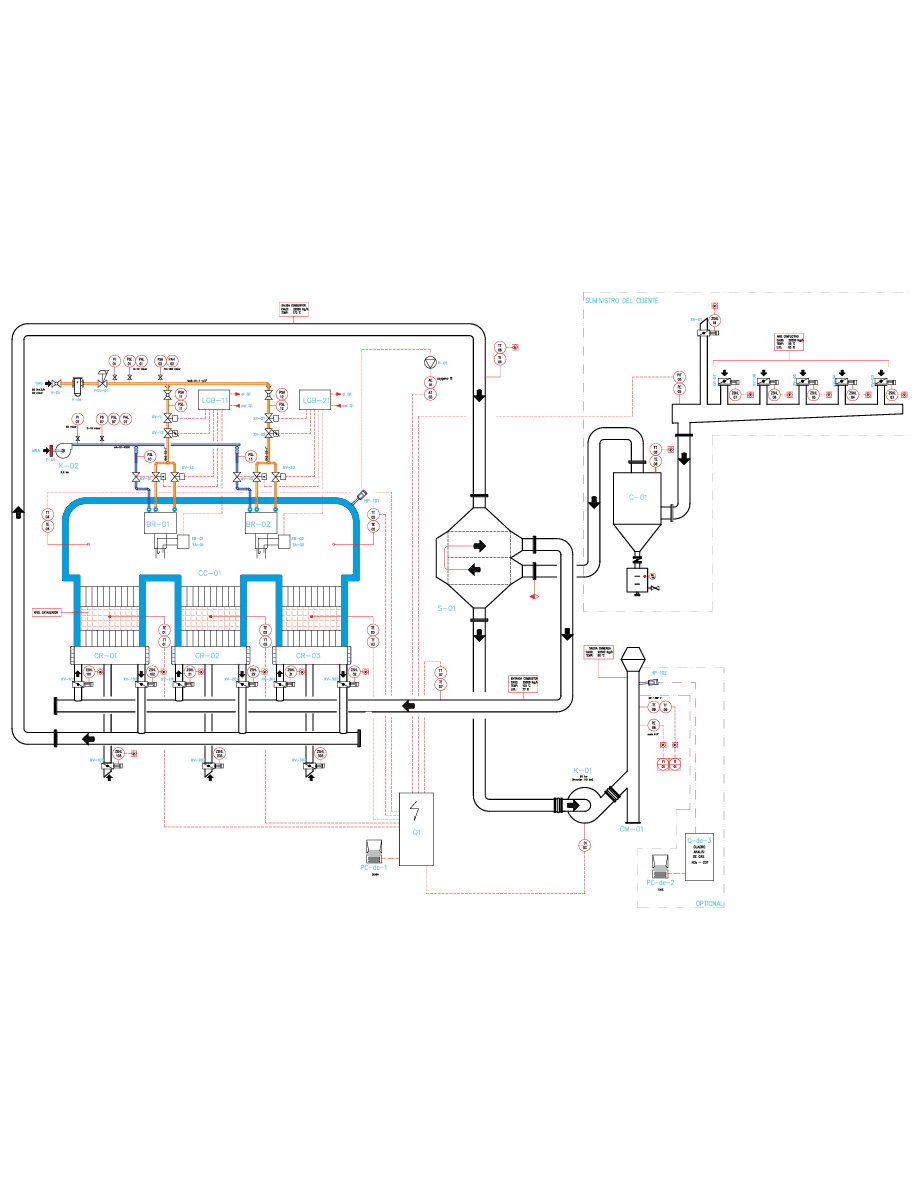

INDUSTRY: Paint (Milan, Italy).

EMISSIONS: Volatile Organic Substances from paint production cycle using solvents (non-chlorinated).

SYSTEM: 3-chamber regenerative oxidizer with zeolite rotor-concentrator.

FLOW RATE: 50,000 Nmc/h from the process, 5,000 Nmc/h concentrated from the rotor-concentrator.